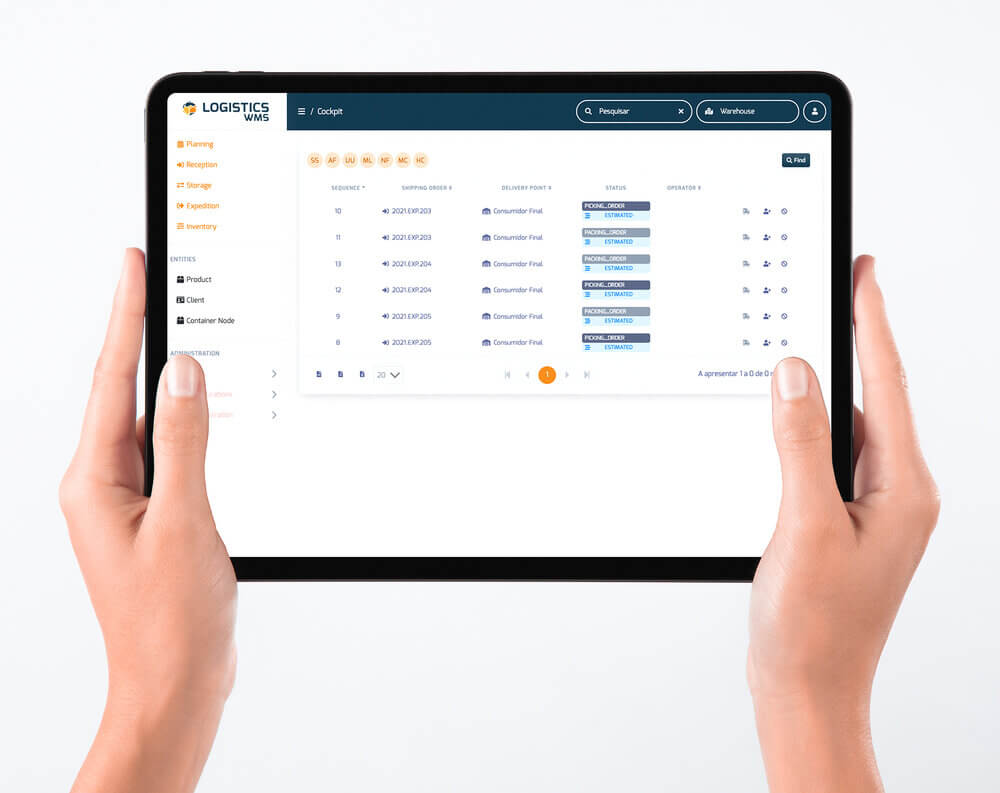

Planning Operations (cockpit)

A few years ago, the logistics sector was seen only as being responsible for the transport, management and distribution of goods.

However, nowadays it plays an essential role in the interconnection of all sectors of the company.

Logistics is extremely important for the company to be successful in reducing costs and growing with efficiency.

The process planning must be seen as a strategic point, which involves the understanding of all the variables that affect the process of operations, as we saw in the article “How can you optimize your warehouse’s operational processes?”.

Logistics WMS is an intelligent warehouse management software that assumes the allocation of people in all its processes, ensuring the minimization of time and space travel.

If we focus on the shipping process, the logistics WMS has the cockpit menu which is responsible for controlling the shipping operations, such as:

Consult the picking and packing orders

The warehouse manager is also a team manager and must be able to consult what his/her team has planned for their day-to-day work. Therefore, having a screen that allows this consultation helps in organizing and optimizing work.

Assign operators to different picking and packing orders

Be a good team management is one of the fundamental points for the proper functioning of a warehouse. Cockpit allows the assignment and distribution of operators by scheduled tasks.

Give “maximum priority” to any picking and packing order

Imagine that an urgent order has arrived at your warehouse that has to leave today but all your warehouse is already occupied with planned and assigned work. Nevertheless, the order has top priority, how should you do it?

The cockpit menu has the functionality to assign “maximum priority” to picking and packing orders which allows them to go to the beginning of the work queue. So the warehouse operator will start working on that order right away and it will be shipped on time.

Cancel picking and/or packing orders

The same can happen with the need to cancel a picking order. Imagine that you have one of your workers allocated to an order from a Customer who canceled at the last minute! It must be possible to cancel the process, release the worker and proceed with the other orders.